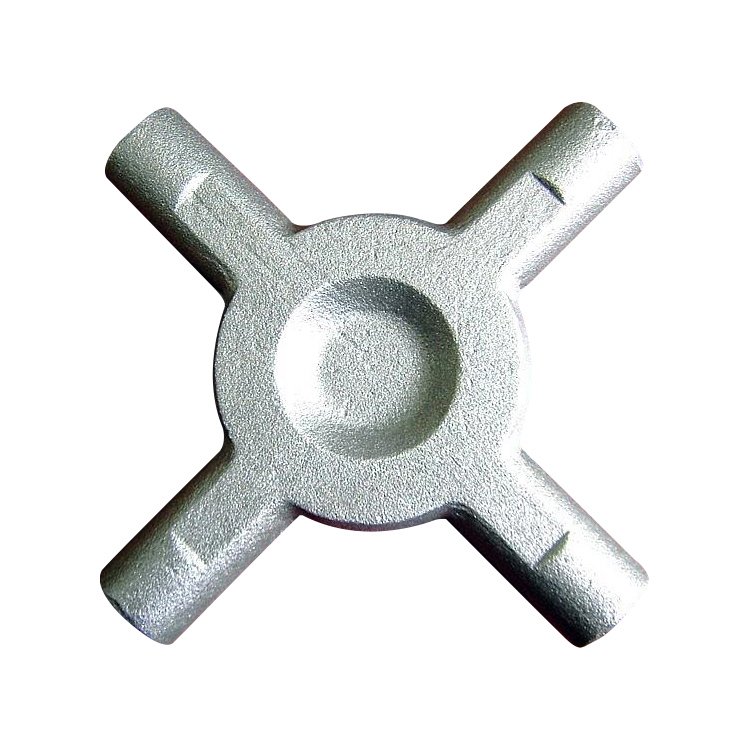

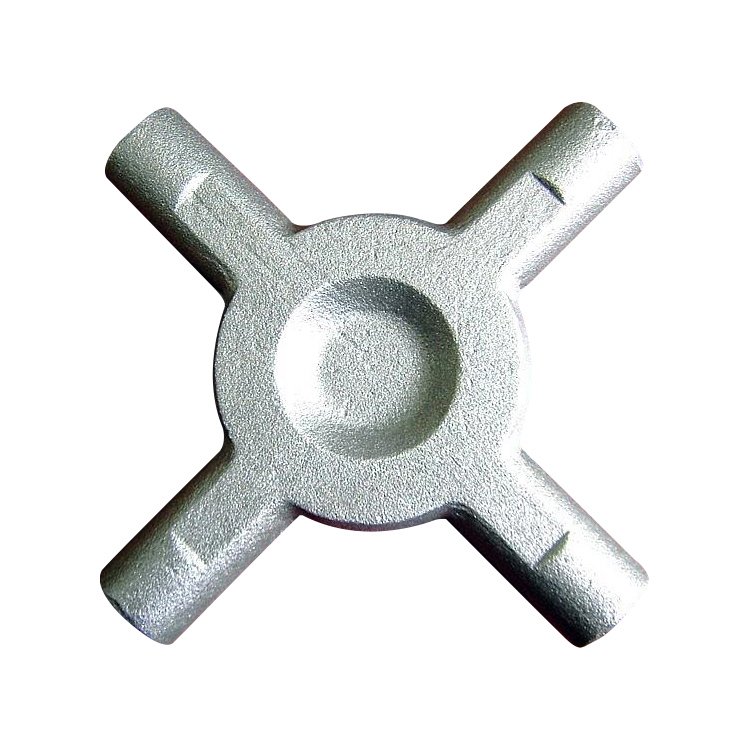

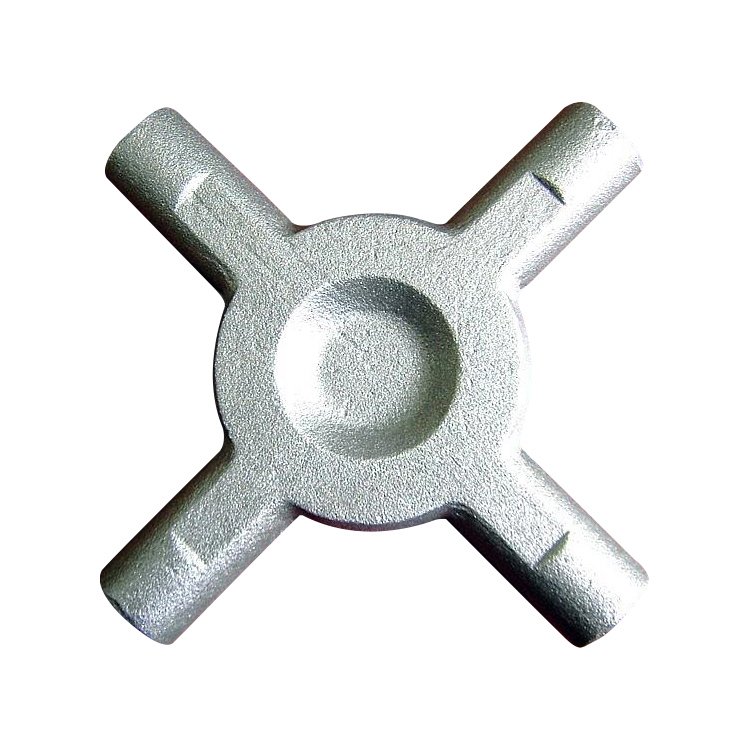

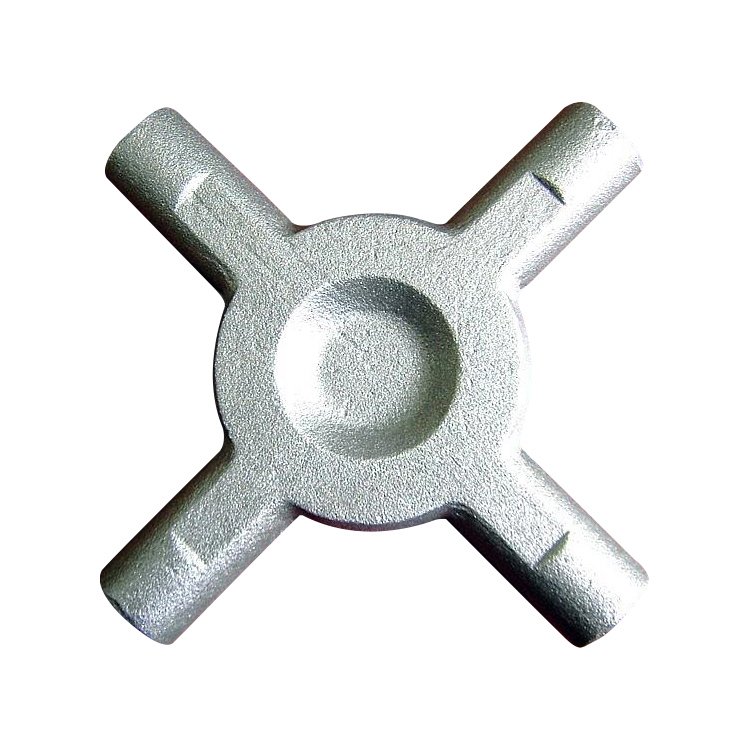

Forged parts of 45 #, 50 #, 40Cr, 201, 304, 316L, 409L rod end joint shaft, cross shaft, and universal joint shaft

Categories: Rod end joint shaft and cross shaft

Brand: Jiucheng

Model: Rod end joint shaft, cross shaft, universal joint shaft

Place of origin: Shandong, China

Our company’s precision forging products for rough parts achieve the goal of no or less turning, saving raw materials and energy, and reducing production costs. The material utilization rate is 50% higher than traditional processes, the comprehensive production cost is reduced by 20%, and the energy-saving rate is over 30%.

Minimum order quantity: 3000 pieces

Price: USD$ 1-20/piece

Payment method: TT settlement

Supply capacity: Annual productivity 1.3 million pieces

Delivery period: 3-20 days to ship

Regular packaging: According to customer requirements, wooden box or carton packaging.

Joint bearing: It is a spherical sliding bearing, which is composed of inner and outer rings with spherical sliding spherical contact surfaces. Joint bearings are mainly composed of an inner ring with an outer spherical surface and an outer ring with an inner spherical surface, which can withstand large loads. According to its different types and structures, it can withstand radial loads, axial loads, or combined loads that exist both radially and axially. Due to the composite material embedded on the outer spherical surface of the inner ring, this bearing can generate self-lubricating during operation. It is generally used for swinging movements with lower speeds, and can also be tilted within a certain angle range. When the support shaft and the shaft shell hole are not concentric, it can still work normally. Self lubricating joint support is applied in industries such as water conservancy and professional machinery. Due to the large spherical sliding contact area and inclination angle of joint bearings, as well as the fact that most joint bearings adopt special processing methods such as surface phosphating, galvanizing, chrome plating, or external sliding surface lining, pad insertion, spraying, etc. Therefore, it has a large load capacity and impact resistance, and has the characteristics of corrosion resistance, wear resistance, self centering, good lubrication or self-lubricating without lubricating dirt pollution. Even if installed incorrectly, it can work normally. Therefore, joint bearings are widely used for lower speed swing, tilt, and rotation movements.

Universal joint: By utilizing the characteristics of its mechanism, the two shafts can rotate continuously and reliably transmit torque and motion when they are not on the same axis and there is an angle between the axes. The biggest feature of a universal joint is that its structure has a large angular compensation ability, a compact structure, and high transmission efficiency. The angle between the two axes of different structural types of universal couplings is not the same, generally between 5 ° -45 °.

The cross shaft universal joint is a widely used universal joint, and the bearing is a vulnerable part of the cross shaft universal joint. The main difference between several large cross shaft universal couplings lies in the changes in the bearing seat and cross head, forming different structural forms. To ensure the synchronization of the main and driven shafts, a double connection form is adopted in practical applications. The double connection method is nothing more than welding or flange plate connection through bolts, and there can be various forms of changes in the length of the middle. Both heavy-duty and small-sized cross shaft universal couplings are universal types, and different models in the automotive industry have their own dedicated cross shaft universal couplings or other types of universal couplings. In addition, agricultural machinery, industrial machinery and other sports machinery products also have dedicated universal couplings, and most of them use cross shaft universal couplings.

We are a Chinese forging manufacturer with over 20 years of experience in the forging industry. Our forged products have been welcomed by a large number of customers in the North and South American markets.

Forged products have competitive prices, excellent quality, and precision forged products achieve the goal of no or less turning, saving raw materials and energy, and reducing production costs. The material utilization rate is 50% higher than traditional processes, the comprehensive production cost is reduced by 20%, and the energy-saving rate is over 30%. Support on-site inspections at the factory, video calls at any time, and 24/7 technical support.

Our factory has inspection and experimental equipment: impact testing machine, notch tensile machine, cloth hardness tester, universal material testing machine, metallographic analysis system, metallographic polishing machine - notch tester. The factory test certificate is provided with the goods. If necessary, third-party inspections can be accepted.

We maintain good quality and competitive prices to ensure that our customers benefit; We respect every customer as a friend and sincerely do business and make friends with them. No matter where they come from.

You can leave us a message and we will reply to each message promptly. We can also have online conversations and communication.

Yes, please feel free to contact us for more detailed information.

The buyer sends a specific product inquiry ->the buyer receives the quotation ->order confirmation ->the buyer sends a deposit ->the seller prepares the goods ->the seller conducts a strict inspection ->the buyer arranges for balance payment ->packaging and delivery.

Our company has been engaged in forging processing business for many years, and we have international experience and expertise. We can provide customers with various high-quality forging products. Our service formula: high quality and good price+excellent service=customer trust.

Quality is the foundation of enterprise survival, innovation is the path of enterprise development, and ideas determine the way out. Jiucheng Company is willing to sincerely cooperate with you, achieve mutual benefit and win-win results, so that customers can obtain excellent product performance, create industry value as you wish, create excellence together, and continue brilliance.