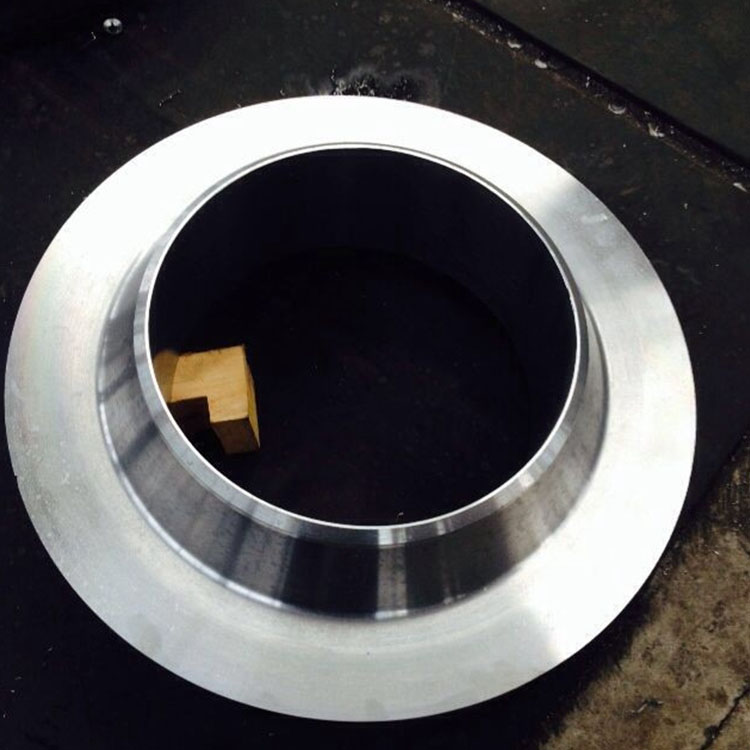

201, 304, 316L flanges, automotive gears, rotary supports, medical and industrial forged parts

Categories: Stainless steel forgings

Brand: Jiucheng

Model: Customizing with pictures

Certification: China Fangyuan

Origin: Shandong China

Our company’s precision forging products for rough parts achieve the goal of no or less turning, saving raw materials and energy, and reducing production costs. The material utilization rate is 50% higher than traditional processes, the comprehensive production cost is reduced by 20%, and the energy-saving rate is over 30%.

Minimum order quantity: 5000

Price: USD$ 3-120/piece

Payment method: TT settlement

Supply capacity: Annual productivity 1.5 million pieces

Delivery period: 3-20 days to ship

After the hot working deformation of stainless steel forging method, due to the deformation and recrystallization of stainless steel, coarse dendrites and columnar grains become finer and uniformly sized equiaxed recrystallized structures, which compact and weld the original segregation, looseness, slag inclusion, etc. in the steel ingot, and improve the mechanical properties. The use of die forging can ensure that the parts have mechanical properties and long service life, which are incomparable to castings. Forging can eliminate defects such as casting porosity in metals during the smelting process, optimize the microstructure, and generally improve the mechanical properties of forgings compared to castings of the same material.

1. The application of stainless steel forgings in the power and smelting industries

In order to save energy, reduce environmental pollution, and extend the service life of some components in power plants, their materials are being replaced with stainless steel forgings. Some equipment in the smelter operates in harsh environments. Due to the severe corrosion of components made of ordinary materials working in a corrosive atmosphere, stainless steel forgings have been used to extend the service life of the equipment.

2. The application of stainless steel forgings in the papermaking industry

Although chemical drugs are not used in the mechanized pulp production process and the degree of corrosion is relatively light, the paper industry emphasizes cleanliness. If the mechanical equipment is made of ordinary steel, it is inevitable to produce rust over time, which will pollute the pulp. Therefore, stainless steel is widely used for manufacturing. In order to reduce pollution and facilitate maintenance during the production of paper, equipment and pipelines such as cooling towers, acid drums, and cooking pots used in the papermaking process are also widely made of stainless steel.

3. Application of stainless steel forgings in reducing environmental pollution

At present, the global emissions of sulfur dioxide are about 140 million tons per year, seriously damaging people’s physical and mental health. The equipment for refining sulfur dioxide is extensively made of stainless steel forgings, and there is a large amount of dust in the air, especially in dusty workplaces (factories, mines). In order to reduce the damage of dust to people, stainless steel forgings are also widely used in dust removal devices. In the sewage treatment process of cities and factories, impurities and added chemicals in the water will corrode the water treatment equipment. In order to extend the service life of sewage treatment equipment, non induced steel manufacturing is also commonly used.

4. Application of stainless steel forgings in marine engineering

In the new historical era, developing the ocean and desalination of seawater is an important issue we face. The oxygen content, chloride ion concentration, relative flow rate between seawater and materials, flow mode, pollution of seawater, and marine organisms all have an impact on corrosion. Common forms of corrosion include uniform corrosion, pitting corrosion, crevice corrosion, and stress corrosion cracking. The medium environment for seawater desalination is degassed seawater and fresh seawater. Stainless steel forgings have been successfully applied to components such as pumps, shafts, shells, impellers, rods, and separators for evaporation tanks in seawater desalination. Stainless steel forgings have also been widely used in seawater development machinery and structures in contact with seawater. Stainless steel forgings have good mechanical properties and resistance to local corrosion, especially better resistance to chloride pitting and crevice corrosion, making them ideal materials in seawater environments. Not only can it be used to manufacture spiral propellers, shafts, submarine seals, etc. for offshore ships, but it is also a good material for manufacturing seawater heat exchangers.

We are a Chinese forging manufacturer with over 20 years of experience in the forging industry. Our forged products have been welcomed by a large number of customers in the North and South American markets.

Forged products have competitive prices, excellent quality, and precision forged products achieve the goal of no or less turning, saving raw materials and energy, and reducing production costs. The material utilization rate is 50% higher than traditional processes, the comprehensive production cost is reduced by 20%, and the energy-saving rate is over 30%. Support on-site inspections at the factory, video calls at any time, and 24/7 technical support.

Our factory has inspection and experimental equipment: impact testing machine, notch tensile machine, cloth hardness tester, universal material testing machine, metallographic analysis system, metallographic polishing machine - notch tester. The factory test certificate is provided with the goods. If necessary, third-party inspections can be accepted.

We maintain good quality and competitive prices to ensure that our customers benefit; We respect every customer as a friend and sincerely do business and make friends with them. No matter where they come from.

You can leave us a message and we will reply to each message promptly. We can also have online conversations and communication.

Yes, please feel free to contact us for more detailed information.

The buyer sends a specific product inquiry ->the buyer receives the quotation ->order confirmation ->the buyer sends a deposit ->the seller prepares the goods ->the seller conducts a strict inspection ->the buyer arranges for balance payment ->packaging and delivery.

Our company has been engaged in forging processing business for many years, and we have international experience and expertise. We can provide customers with various high-quality forging products. Our service formula: high quality and good price+excellent service=customer trust.

Quality is the foundation of enterprise survival, innovation is the path of enterprise development, and ideas determine the way out. Jiucheng Company is willing to sincerely cooperate with you, achieve mutual benefit and win-win results, so that customers can obtain excellent product performance, create industry value as you wish, create excellence together, and continue brilliance.